What is Diamond wire? Method of using Diamond wire for stone quarrying and concrete and matters needing attention?

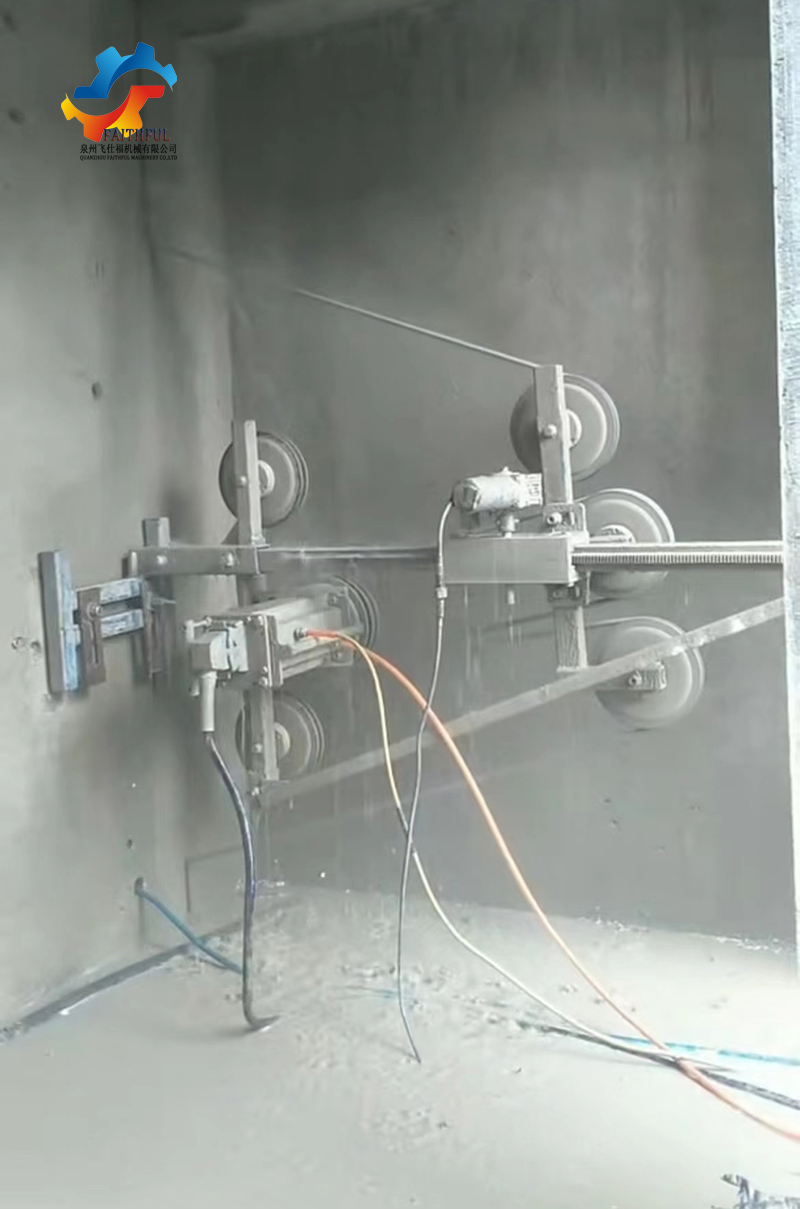

一、What is the Diamond wire saw for stone quarrying and concrete used for?

Used for stone quarrying, such as granite, marble, limestone, sandstone and etc

It may also used in construction fields, such as bridge, housing, subway construction,

concrete,demolition, subsea use, steel pipe and etc

二、How to classify Diamond wire saw by use?

Diamond Wire for Granite Quarrying、Marble Quarrying、Reinforced Concrete、

Multi-wire for Slab Cutting、 Diamond Wire for Squaring& Profiling

Diamond Wire for Granite Quarrying

Diamond Wire for Reinforced Concrete

Diamond Wire for Marble Quarrying

Diamond Wire for Squaring& Profiling

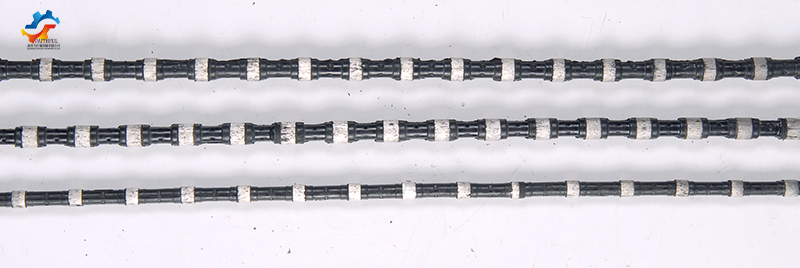

三、How to classify Diamond wire saw from the production process?

Diamond bead has sintered bead, electroplated bead,vacuum brazed bead from the production process

Vacuum brazed bead

Vacuum brazed bead

electroplated bead

四、What is a Diamond wire saw made of?

Diamond beads, cable (commonly used diameter φ4.9, φ3.85, φ3.6) filler (spring, rubber, plastic)

五、The use of Diamond wire saw should pay attention to what matters?

1、Water must be added in moderation

Adding too much water is easy to polish, adding too much water will lead to high temperature scrap

2、Abnormal beads should be cut off

Broken, degummed beads need to be cut to avoid adverse effects

3、Need protective net protection

Avoid wire rope or bead flying injury

4、Store in the shade

Rubber ages easily and needs to be stored in a cool place

六、What faults can exist when Diamond wire saw are used? How to troubleshoot?

What causes the displacement of the beads on the diamond saw? How to solve

What cou![]() ld be the cause?

ld be the cause?

(1)Too much tension on the Diamond wire saw

(2)Too high temperature

(3)The Diamond wire saw is stuck

(4)Stone with more gaps

Solution?

(1)Reduce feed speed

(2)Increased cooling

(3)Place wedges in the cut gaps

(4)Use a rubber spring rope

![]() If the diamond rope saw bead taper is what cause? How to solve it?

If the diamond rope saw bead taper is what cause? How to solve it?

What could be the cause?

(1)Stone is very abrasive

(2)Small cutting surface

(3)Under cooling

(4)Low linear velocity

Solution?

(1)Reformulation

(2)High line speed low feed

(3)Enhanced cooling

(4)Increase linear velocity

![]() What are the causes of broken rope saw?

What are the causes of broken rope saw?

(1)The wire rope is broken near the joint

Because the joint is rigid, in the cutting process does not bend with the flywheel, resulting in the joint near the wire rope Angle is very large, with the extension of time, the number of bending, easy to fatigue fracture, plus with the cutting, the joint will slowly pull out, the area of water and sediment easy to enter, further aggravate the breaking speed.

(1)Diamond wire bead breakage in the process of use

When beads are damaged, they are not cut off in time. With the entry of sediment and the oxidation of the wire rope itself in the water environment, the area is prone to broken rope.

(3) The edges are too sharp for use

The edge and corner of the cutting material are too sharp, resulting in a certain Angle of steel wire bending, the greater the degree of bending, the more times of repeated bending, steel wire fatigue leads to broken rope, and the edge and corner sharp is also easy to cause rubber damage.

(4) Bead outside diameter difference is large when used

Beads outside diameter difference is larger, when the smaller beads through the stone seam, and the larger outside diameter beads failed to pass, there will be a card rope situation, and then may appear to break the rope.

(5) The linear velocity is not reduced at the end

At the end, the high linear velocity is still maintained, which is a phenomenon that is often ignored and may cause rope breaking. At the end, the cutting surface is small and the complete degree of the wire rope is large. If the linear velocity remains unchanged, the frequency of wire rope bending will increase and fatigue fracture will be more likely to occur.

(6) The rope tension is too high or the rope shakes badly

If the rope tension is too large, the linear velocity is low and the current is large, the rope may be broken due to the large rope tension. At the same time, the rope jitter is serious, and it is easy to break the rope.

In addition, when there is a rope break, because the rope may be thrown out of the rope, then more likely to break the rope.

![]() The string of beads is offset

The string of beads is offset

What could be the cause?

(1) The rope looped too little

(2) There is too much tension on the rope

(3) Under cooling

(4) The flywheel is too short from the cutting material

Solution?

(1) Increase the number of laps per meter

(2) Reduce the feed rate

(3) Enhanced cooling

(4) Increase the distance between them

![]() Diamond wire saw Not cutting or cutting slowly

Diamond wire saw Not cutting or cutting slowly

What could be the cause?

(1) The sharpness of the formula is not enough

(2) Excessive linear velocity

(3) The cutting surface is too wide

(4) Low current

Solution?

(1) Reformulation

(2) Linear velocity reduction

(3) Increase the current and decrease the linear velocity

(4) Increase current

![]() The diamond wire saw burned too much rubber

The diamond wire saw burned too much rubber

Bead matrix rubber cracking, rubber surface is not glossy, sticky touch

What could be the cause?

Water shortage, add water itself is not enough, or stone cracks caused by some parts of the water shortage

Solution?

Add cooling water or increase the number of cooling pipes.

![]() Diamond wire saw rubber cracked

Diamond wire saw rubber cracked

What could be the cause?

Caused by broken surface and gravel, the later operation process is expanded

Solution?

Clear the rubble and cut off the broken rubber if possible

![]()

八、About us

Quanzhou Faithful Machinery Co., Ltd is a professional manufacturer and exporter of stone machinery,diamond tools,stone care products, concrete cutting equipment and tools. Customized products and solutions are available to meet their satisfaction.

Faithful Machinery boasts a professional team of skilled experts, managerial talents with modern management consciousness and high quality marketing staffs with proficiency in business expertise,such as Mr Lei,Doctor of Chemistry from Texas Agriculture University,Senior Technical Engineer from Wuhan University with over 20 years of experience in the fields,which ensures the sustained and solid services and supports for the customers from home and abroad.

Faithful Machinery Group consists of the following companies and factories.

QUANZHOU HUANQIU MACHINE CO.,LTD

QUANZHOU UNIVERSAL DIAMOND TOOLS CO.,LTD

Russian ООО "ТК ГП"

BRAIZLIAN FAITHFUL MACHINERY CO,. LTD

MYANMAR OCEAN BUILDING MATERIAL CO., LTD

Joint ventures:

XIAMEN MURAT IMPORT& EXPORT CO.,LTD ,which is specialized in concrete cutting, grinding and polishing.

USA Sinobase Corporation is devoted to chemical products, stone or floor caring, AB adhesives, waterproof adhesives,etc

Faithful Machinery, basing in China,walking up to the world since it’s establishment, has been providing high-quality products and services for stone people and stone companies China-wide and globally for more than 80 countries in a purpose to create a stone realm of fancy with our full exertions.

Faithful Machinery has been cherishing and advocating such ideas as opening,inclusiveness,cooperativeness and win-win policy to work with you for a better world

九、Contact us

Quanzhou Faithful Machinery Co.,LTD.

Cell:+86-13599229330

Fax:+86-595-85705516

Email:info@faithfultool.com

Address:No. 12-2, Lingyuan North Road, Lingyuan, Jinjiang, Quanzhou, Fujian, China

Post Code:362200

Website:www.faithfultool.com

www.faithfulmachinery.com